Transparent panels constructed from a durable thermoplastic polymer offer a shatter-resistant alternative to traditional glazing materials. These panels find application across various sectors, providing light transmission coupled with impact resistance. Examples include use in security barriers, skylights, and vehicle components.

The adoption of this robust material provides enhanced safety and security due to its significantly higher impact strength compared to glass. This feature is particularly valuable in environments susceptible to vandalism or accidental damage. Historically, its introduction marked a significant advancement in glazing technology, offering a lighter and more resilient option.

The subsequent sections will detail the specific properties, advantages, installation considerations, and maintenance requirements pertinent to understanding the effective utilization of this advanced glazing solution.

1. Impact Resistance

The substantial impact resistance is a defining characteristic of polycarbonate windows, fundamentally differentiating them from traditional glass. The polymeric structure of polycarbonate allows it to absorb and dissipate energy from impacts, preventing shattering. This attribute stems from the material’s capacity to undergo significant deformation without fracturing, a behavior not exhibited by brittle materials like glass. Real-world applications underscore this point: security barriers employing polycarbonate sheets withstand forceful attempts at breach, and vehicle windows constructed from this material offer occupants enhanced protection during collisions. The selection of polycarbonate for these applications is directly driven by the need for superior impact performance.

Suggested read: Download Hazbin Hotel Windows Theme - [Year]

The degree of impact resistance is often quantified using standardized tests, such as those outlined by ASTM International. These tests measure the energy required to fracture the material under specific conditions. Polycarbonate consistently demonstrates significantly higher impact resistance compared to glass of similar thickness. Furthermore, the material’s resistance to impact varies depending on factors like temperature and sheet thickness, necessitating careful consideration during the design and selection process for particular applications. For instance, cold environments may reduce impact resistance, requiring thicker polycarbonate sheets or specialized formulations.

In summary, the exceptional impact resistance is not merely a feature of polycarbonate windows; it is an inherent and critical property that dictates its suitability for a wide array of applications where safety, security, and durability are paramount. The understanding of its cause and effect is vital for optimizing its use and mitigating potential vulnerabilities, ensuring long-term performance and reliability in demanding environments.

2. Optical Clarity

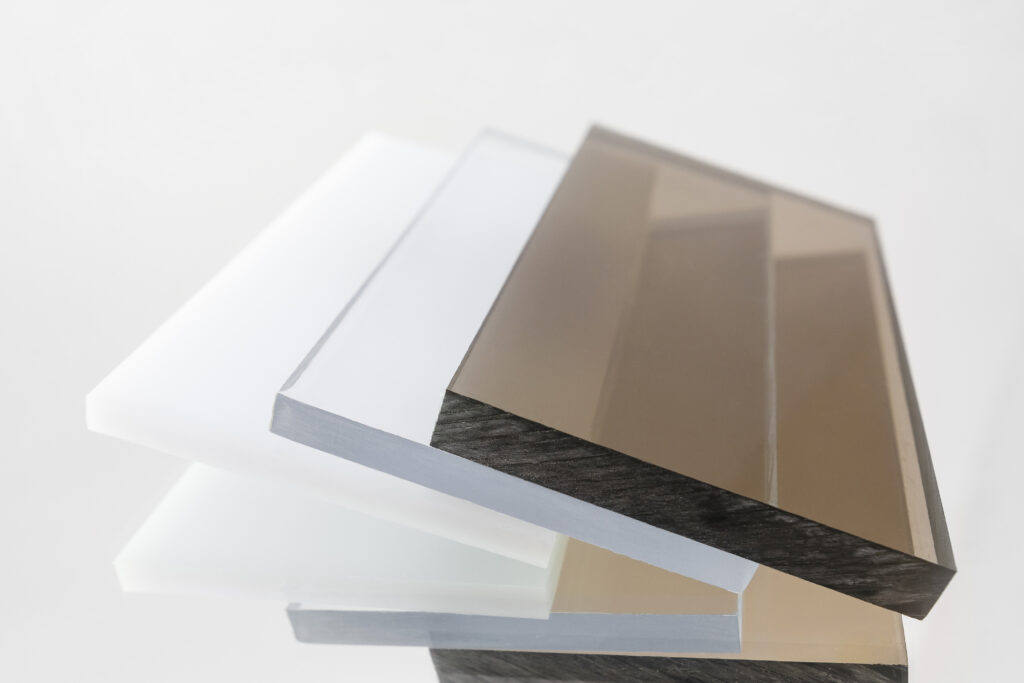

Optical clarity is a key attribute influencing the suitability of polycarbonate windows for various applications. While polycarbonate offers superior impact resistance compared to glass, its inherent optical properties directly affect visibility and light transmission. The clarity of the polycarbonate determines the quality of light passing through the window, impacting visual acuity and the aesthetic appeal of the application. For example, in architectural glazing, high optical clarity ensures that the aesthetic design is not compromised by distorted views or reduced light levels within the building. Conversely, lower optical clarity could be acceptable or even desirable in applications where privacy or light diffusion is paramount, such as in some industrial or security settings.

Achieving optimal optical clarity in polycarbonate windows is influenced by several factors, including the manufacturing process, the grade of polycarbonate resin used, and any surface treatments applied. Impurities or inconsistencies in the resin can lead to haziness or discoloration, reducing light transmission. Similarly, scratches or abrasions on the surface can scatter light, diminishing clarity. To mitigate these issues, manufacturers employ specialized extrusion and molding techniques, along with scratch-resistant coatings, to enhance and maintain optical properties. The selection of appropriate cleaning agents is also crucial for preserving the clarity of polycarbonate windows over their lifespan. Improper cleaning methods can lead to surface damage, negating the benefits of protective coatings.

In conclusion, the relationship between optical clarity and polycarbonate windows is a critical consideration in material selection and application design. The degree of clarity required is application-specific, ranging from high transparency for architectural purposes to controlled diffusion for privacy or light management. Understanding the factors that influence optical clarity, from manufacturing processes to maintenance procedures, is essential for maximizing the performance and longevity of polycarbonate windows, ensuring they meet the intended functional and aesthetic requirements.

3. UV Protection

Ultraviolet (UV) radiation poses a significant threat to the long-term integrity and performance of polycarbonate windows. Prolonged exposure to UV rays induces degradation of the polycarbonate polymer, leading to yellowing, embrittlement, and a reduction in impact resistance. Consequently, incorporating UV protection is a critical aspect of manufacturing durable and reliable polycarbonate windows. The inclusion of UV-absorbing additives during the production process mitigates this degradation. These additives selectively absorb UV radiation, preventing it from reaching and damaging the polymer matrix. Without adequate UV protection, polycarbonate windows will experience a diminished service life and compromised performance characteristics. For example, consider a polycarbonate skylight installed without UV protection; it would gradually yellow and become brittle, reducing light transmission and potentially leading to structural failure over time.

The implementation of UV protection strategies extends beyond simple additive incorporation. Surface coatings with UV-absorbing properties offer an alternative or supplementary approach. These coatings provide a sacrificial layer that absorbs UV radiation, protecting the underlying polycarbonate. The effectiveness of UV protection is often quantified through accelerated weathering tests, simulating years of outdoor exposure in a controlled environment. These tests assess the degree of yellowing, loss of impact strength, and other degradation indicators. The selection of appropriate UV protection methods depends on the specific application and environmental conditions. For instance, polycarbonate windows used in high-altitude environments, where UV radiation is more intense, may require more robust protection strategies.

In summary, UV protection is an indispensable component of high-quality polycarbonate windows. Its inclusion is not merely a cosmetic enhancement but a fundamental requirement for ensuring long-term durability, maintaining optical clarity, and preserving structural integrity. Ignoring UV protection results in premature degradation, compromising the functionality and safety of the window. Therefore, understanding the mechanisms of UV degradation and implementing appropriate protective measures is paramount for maximizing the lifespan and performance of polycarbonate windows in diverse applications.

4. Thermal insulation

Thermal insulation, the reduction of heat transfer between spaces, is a crucial performance characteristic for window systems. In the context of polycarbonate windows, insulation capabilities affect energy efficiency, interior comfort, and overall building performance.

-

Multi-Wall Polycarbonate Panels

Multi-wall polycarbonate sheets, featuring multiple layers separated by air gaps, significantly enhance thermal resistance compared to single-layer alternatives. The air gaps impede conductive heat transfer, leading to improved insulation. For instance, greenhouses often employ multi-wall polycarbonate to maintain stable internal temperatures, minimizing heating costs during colder periods. The effectiveness is measured by the U-value, indicating the rate of heat transfer; lower U-values signify better insulation performance.

-

Insulating Glazing Units (IGUs)

Polycarbonate can be integrated into Insulating Glazing Units (IGUs), similar to double-pane glass windows, to create a thermal barrier. An air or gas-filled space is sealed between two polycarbonate sheets, reducing heat transfer. Argon or krypton gas, possessing lower thermal conductivity than air, can further enhance insulation performance. Such IGUs find application in architectural glazing, where minimizing heat loss is essential for energy conservation.

-

Thermal Bridging and Frame Design

The thermal performance of a polycarbonate window system is influenced by the frame material and design. Metal frames, possessing high thermal conductivity, can create thermal bridges, facilitating heat transfer and reducing the overall insulation effectiveness. Incorporating thermally broken frames, featuring a non-conductive material between the interior and exterior sections, mitigates thermal bridging and enhances the system’s insulation capabilities. The frame’s impact on the system’s U-value must be considered during design.

-

Coatings and Films

Suggested read: Illinois Tint Laws: A Window to Compliance

Low-emissivity (Low-E) coatings can be applied to polycarbonate sheets to reduce radiative heat transfer. These coatings selectively reflect long-wave infrared radiation, minimizing heat loss during winter and heat gain during summer. Additionally, spectrally selective films can be applied to polycarbonate windows to filter specific wavelengths of solar radiation, further optimizing thermal performance and reducing glare. The impact of these coatings is measured by the window’s Solar Heat Gain Coefficient (SHGC).

The interplay of these facets underscores the importance of a comprehensive approach to thermal insulation in polycarbonate window systems. Optimizing material selection, frame design, and surface treatments are essential to achieving desired energy efficiency and comfort levels. The suitability of a particular approach is dependent on the specific application, climate conditions, and performance requirements.

5. Weight reduction

The utilization of polycarbonate in window construction offers a significant advantage in weight reduction compared to traditional glazing materials like glass. This disparity stems from the inherent density difference between polycarbonate and glass, with polycarbonate being substantially lighter per unit volume. This attribute is particularly crucial in applications where structural load is a primary concern. Examples include transportation vehicles, such as aircraft and trains, where minimizing weight directly translates to improved fuel efficiency and performance. Similarly, in architectural projects involving large glazed areas, the reduced weight of polycarbonate lessens the demands on supporting structures, potentially leading to cost savings and design flexibility.

The practical significance of this weight reduction extends beyond mere structural considerations. The ease of handling and installation is enhanced due to the lighter nature of polycarbonate sheets. This is especially relevant in situations where access is restricted or labor costs are a significant factor. The lower weight also reduces transportation expenses and the risk of breakage during handling, contributing to a more efficient and economical project lifecycle. Furthermore, the reduced inertial mass of polycarbonate windows can improve safety in dynamic environments, such as vehicles, by minimizing the risk of injury in the event of an impact.

In summary, weight reduction stands as a fundamental benefit derived from employing polycarbonate windows. Its impact spans across structural engineering, transportation efficiency, installation logistics, and safety considerations. Recognizing the magnitude and multifaceted nature of this advantage is essential for making informed decisions regarding glazing material selection, ultimately optimizing performance and minimizing resource consumption in diverse applications.

Frequently Asked Questions About Polycarbonate Windows

The following addresses common inquiries and misconceptions concerning polycarbonate window applications, properties, and performance characteristics.

Question 1: What is the typical lifespan of polycarbonate windows?

Lifespan is contingent on factors including UV exposure, environmental conditions, and maintenance practices. However, with proper UV protection and regular cleaning, polycarbonate windows can maintain structural integrity and optical clarity for 10-20 years.

Question 2: Are polycarbonate windows scratch-resistant?

While offering superior impact resistance, polycarbonate is inherently susceptible to scratching. Application of scratch-resistant coatings enhances surface durability. Cleaning with abrasive materials must be avoided.

Question 3: How does the cost of polycarbonate windows compare to glass?

Initial material costs can be higher than glass. The long-term cost-effectiveness depends on factors such as reduced breakage, lower structural support requirements (due to lighter weight), and enhanced energy efficiency (with multi-wall options).

Question 4: Can polycarbonate windows be tinted or colored?

Polycarbonate can be manufactured in a variety of colors and tints. Surface films can be applied to alter light transmission characteristics, reduce glare, or enhance privacy.

Question 5: How do polycarbonate windows perform in extreme temperatures?

Polycarbonate maintains its impact resistance and structural properties over a wide temperature range, typically from -40C to 120C. Specific formulations may offer enhanced thermal stability.

Question 6: What cleaning agents are suitable for polycarbonate windows?

Mild soap and water solutions are recommended. Abrasive cleaners, solvents, and ammonia-based products should be avoided, as they can damage the surface and reduce optical clarity.

In summary, polycarbonate windows offer a compelling alternative to glass in situations where impact resistance, weight reduction, or enhanced thermal performance are paramount. Informed material selection requires careful consideration of factors like UV protection, scratch resistance, and cleaning requirements.

The succeeding section examines the installation procedures and maintenance guidelines essential for ensuring the enduring performance of this glazing system.

Essential Considerations for Polycarbonate Window Implementation

Effective utilization of polycarbonate glazing necessitates adherence to key principles throughout design, installation, and maintenance phases. These considerations ensure optimal performance, longevity, and safety.

Tip 1: Material Selection Based on Application: Evaluate specific requirements, such as impact resistance, UV exposure, and optical clarity, to select the appropriate polycarbonate grade. Consider multi-wall options for enhanced thermal insulation.

Tip 2: Proper Edge Sealing: Employ compatible sealants and edge profiles to prevent moisture ingress and delamination, especially in outdoor applications. Consult manufacturer specifications for sealant compatibility.

Tip 3: Pre-Drilling for Fasteners: Avoid direct fastening into polycarbonate sheets without pre-drilling. Use oversized holes to accommodate thermal expansion and contraction, preventing stress fractures.

Tip 4: Controlled Torque during Installation: Over-tightening fasteners can induce stress and cracking. Employ torque-limiting tools to ensure consistent and appropriate pressure.

Tip 5: UV Protection Verification: Confirm the presence and effectiveness of UV-protective coatings or additives. Re-apply coatings periodically as recommended by the manufacturer.

Tip 6: Avoid Abrasive Cleaning: Refrain from using abrasive cleaners, solvents, or scouring pads. Utilize mild soap and water solutions with soft cloths to prevent scratching.

Suggested read: Pro Mobile Tint Windows: Near You Today!

Tip 7: Regular Inspection and Maintenance: Conduct periodic inspections for signs of damage, discoloration, or sealant degradation. Promptly address any issues to prevent further deterioration.

Adherence to these guidelines ensures that polycarbonate windows deliver the expected performance characteristics, including impact resistance, optical clarity, and thermal insulation, over an extended service life.

The subsequent section provides a summary of the key advantages and applications discussed throughout this article, reinforcing the value proposition of polycarbonate glazing solutions.

Conclusion

This exploration of polycarbonate windows has highlighted key attributes including superior impact resistance, optical clarity considerations, UV protection necessities, thermal insulation potential, and weight reduction benefits. Successful implementation hinges on careful material selection, proper installation techniques, and diligent maintenance practices. The information provided facilitates informed decision-making regarding this glazing alternative across diverse applications.

Given the increasing demands for safety, energy efficiency, and design flexibility in modern construction and transportation, the continued development and refinement of polycarbonate window technology remains a critical endeavor. Further research into enhanced scratch resistance, improved UV protection methodologies, and optimized thermal performance will solidify the position of polycarbonate windows as a viable and valuable solution for glazing needs.

![Download Hazbin Hotel Windows Theme - [Year] 4 download hazbin hotel windows theme year](https://superagc.com/wp-content/uploads/2025/10/download-hazbin-hotel-windows-theme-year.jpg)