The query regarding the feasibility of applying a coating to polyvinyl chloride (PVC) window frames is frequently posed. The possibility depends significantly on factors such as surface preparation, paint selection, and environmental conditions during application. Success hinges on ensuring proper adhesion of the coating to the inherently smooth, non-porous surface of the vinyl material. For instance, using a paint specifically formulated for plastics, accompanied by meticulous cleaning and priming, increases the likelihood of a durable and aesthetically pleasing result.

Addressing the issue of whether a PVC window frame can accept a new color is important because color modifications can enhance a home’s curb appeal, modernize its appearance, or correct fading caused by prolonged sun exposure. Historically, painting such frames was discouraged due to concerns about paint failure, peeling, or warping of the vinyl. However, advancements in coating technology have led to the development of products designed to adhere reliably to these materials, offering homeowners a viable option for customizing their windows.

The following sections will delve into the preparatory steps crucial for a successful application, examine the types of coatings best suited for PVC, and discuss potential challenges and best practices to consider when undertaking this project. These aspects provide a framework for understanding the intricacies involved in altering the color of PVC window frames.

1. Surface Preparation

The success of any attempt to alter the color of PVC window frames is inextricably linked to the quality of surface preparation. Prior to the application of any coating, the PVC surface must be rendered completely clean and free of contaminants. The inherently smooth, non-porous nature of vinyl poses a significant challenge to paint adhesion. Residual dirt, grease, mold, or even oxidation can act as a barrier, preventing the coating from properly bonding to the substrate. This inadequate bond invariably leads to premature peeling, blistering, or cracking of the paint film, regardless of the quality of the coating itself. For example, a window frame exposed to environmental pollutants will require thorough cleaning with a specialized degreaser to remove any oily residues that could compromise paint adhesion. This step is not merely cosmetic; it is a fundamental prerequisite for achieving a durable and long-lasting finish.

The specific methods employed in surface preparation can vary depending on the age and condition of the PVC. New frames may only require a simple cleaning with a mild detergent solution to remove manufacturing residues. Older frames, however, often necessitate more aggressive cleaning techniques. This may involve the use of specialized PVC cleaners designed to remove oxidation and ingrained dirt without damaging the underlying material. In some instances, a light abrasion of the surface with fine-grit sandpaper can further improve adhesion by creating a microscopic texture for the paint to grip. The use of a bonding primer, specifically formulated for application to plastics, is frequently recommended as an additional step to promote adhesion and create a uniform surface for painting. Improperly prepared surfaces represent a common pitfall, often resulting in costly rework and frustration for homeowners attempting to change the color of their PVC windows.

In summary, surface preparation is not simply a preliminary step; it is the foundation upon which the entire success of the painting process rests. Neglecting this crucial phase increases the likelihood of paint failure, thereby undermining the intended aesthetic improvement and potentially damaging the PVC frame itself. Therefore, meticulous attention to detail and the use of appropriate cleaning and priming techniques are paramount when attempting to apply a coating to PVC window frames.

Suggested read: Read Provia Windows Reviews: Are They Worth It?

2. Appropriate Paint Selection

The core question of whether PVC window frames can be painted hinges significantly on the selection of an appropriate coating. The application of standard, general-purpose paint formulations to PVC is likely to result in adhesion failures, peeling, cracking, or discoloration. This stems from the inherent properties of PVC, including its low surface energy and susceptibility to expansion and contraction with temperature fluctuations. Therefore, the selection of a paint specifically formulated for use on vinyl or plastic substrates is paramount to the success of any painting endeavor. These specialized coatings are engineered to exhibit superior adhesion, flexibility, and UV resistance, thereby mitigating the risk of premature failure. For example, acrylic latex paints designed for vinyl siding incorporate plasticizers that allow the coating to expand and contract with the PVC, preventing cracking and peeling caused by thermal expansion.

The detrimental effects of improper paint selection are evident in numerous real-world scenarios. Homes where standard exterior paints have been applied to PVC window frames often exhibit significant paint degradation within a short period. This not only detracts from the aesthetic appeal of the property but also necessitates costly repainting, often involving extensive surface preparation to remove the failed coating. Furthermore, improper paint selection can compromise the integrity of the window frame itself. Dark-colored paints, in particular, can absorb excessive solar radiation, leading to increased heat buildup in the PVC. This, in turn, can cause the frame to warp or distort, potentially affecting the window’s functionality and energy efficiency. The practical significance of understanding the connection between appropriate paint selection and the successful alteration of PVC window frame colors is therefore undeniable.

In summary, the selection of a coating specifically formulated for use on PVC is a critical determinant of whether a successful and durable paint job can be achieved. Failure to adhere to this principle will likely result in significant performance issues, necessitating rework and potentially damaging the window frame. The availability of specialized paints designed for plastics offers homeowners a viable option for customizing the appearance of their windows, provided that proper selection criteria are applied. These criteria prioritize adhesion, flexibility, and UV resistance to ensure long-term performance and aesthetic satisfaction.

3. Proper Application Technique

Successful alteration of PVC window frame color hinges significantly on the employment of proper application techniques. Even with meticulous surface preparation and the selection of specialized coatings, deviations from established application protocols can undermine the integrity and longevity of the finish.

-

Thin, Even Coats

Applying multiple thin, even coats is preferable to a single, thick coat. Thick coats are prone to sagging, runs, and extended drying times, increasing the likelihood of surface imperfections and compromising adhesion. For instance, the application of thin coats allows each layer to properly bond with the underlying surface, promoting a stronger and more durable finish that resists peeling and cracking over time.

-

Appropriate Drying Times

Adherence to recommended drying times between coats is crucial. Premature application of subsequent coats can trap solvents, leading to blistering and solvent popping. The consequences of disregarding drying times are evident in coatings that exhibit a soft, tacky texture long after the intended curing period, indicating incomplete solvent evaporation and compromised film formation.

-

Spray vs. Brush Application

The choice between spraying and brushing impacts the final finish. Spraying typically yields a smoother, more uniform appearance, minimizing brush strokes. However, it requires proper equipment and technique to avoid overspray and uneven coverage. Brush application, while simpler in terms of equipment, necessitates careful attention to detail to prevent brush marks and ensure consistent paint distribution. The selection should be based on desired aesthetic outcome and level of applicator skill.

-

Environmental Conditions

Application during optimal environmental conditions is essential. Extreme temperatures or high humidity can adversely affect paint curing and adhesion. For example, applying paint in direct sunlight can cause the surface to overheat, leading to rapid solvent evaporation and poor adhesion. Conversely, high humidity can impede drying and promote the formation of a milky or cloudy film on the painted surface. Adhering to the paint manufacturer’s recommended temperature and humidity ranges is paramount for achieving a durable and aesthetically pleasing finish.

These facets of proper application technique, when diligently followed, contribute significantly to the overall success of any project involving coating PVC window frames. Disregarding these protocols introduces a higher probability of premature coating failure, thereby negating the benefits of specialized paints and meticulous surface preparation. The application process is thus an integral component in determining the ultimate viability of changing the color of PVC window frames.

4. Weather Conditions

The ambient environment plays a decisive role in the success or failure of altering the color of PVC window frames. The interaction between atmospheric conditions and the applied coating dictates factors ranging from adhesion strength to long-term durability. Understanding the influence of temperature, humidity, and precipitation is, therefore, paramount.

-

Temperature Range

Adherence to the paint manufacturer’s specified temperature range is critical during application and curing. Extreme temperatures, both high and low, can negatively impact the paint’s ability to properly adhere to the PVC surface. High temperatures can accelerate solvent evaporation, leading to poor film formation and compromised adhesion. Conversely, low temperatures can retard the curing process, resulting in a soft, tacky finish that is susceptible to damage. For instance, applying paint to a PVC window frame on a day with temperatures exceeding 90F (32C) may result in blistering and premature peeling, even if a specialized vinyl paint is used. Precise temperature control is thus indispensable.

-

Humidity Levels

Elevated humidity levels can impede the drying and curing process of coatings applied to PVC window frames. High moisture content in the air can slow the evaporation of solvents, leading to prolonged drying times and a higher risk of defects, such as blistering or a milky appearance. Furthermore, excessive humidity can create a condensation layer on the PVC surface, interfering with paint adhesion. For example, a project undertaken on a day with 80% humidity may experience significantly longer drying times and a greater likelihood of imperfections compared to a similar project completed under drier conditions. Maintaining humidity levels within the paint manufacturer’s recommended range is vital for optimal results.

-

Precipitation Exposure

Exposure to rain or other forms of precipitation during or immediately after painting PVC window frames can irreparably damage the finish. Water can wash away uncured paint, leading to uneven coverage and compromised adhesion. Furthermore, moisture intrusion can cause blistering and peeling, particularly in areas where the paint film is thin or incomplete. Consequently, meticulous planning is essential to ensure that the painting project is undertaken during a period of stable weather with no anticipated precipitation. A sudden rain shower during the curing phase can necessitate a complete reapplication of the coating.

-

Direct Sunlight

While sunlight provides warmth conducive to curing, direct and intense sunlight can cause the PVC surface to overheat, leading to accelerated solvent evaporation and poor adhesion. Additionally, prolonged exposure to direct sunlight can cause the paint film to fade or discolor over time, particularly if the chosen coating lacks adequate UV protection. Shading the work area or scheduling the painting project for a time of day when direct sunlight is minimized can mitigate these risks. Implementing measures to control sunlight exposure is a crucial component of ensuring a durable and aesthetically pleasing finish on PVC window frames.

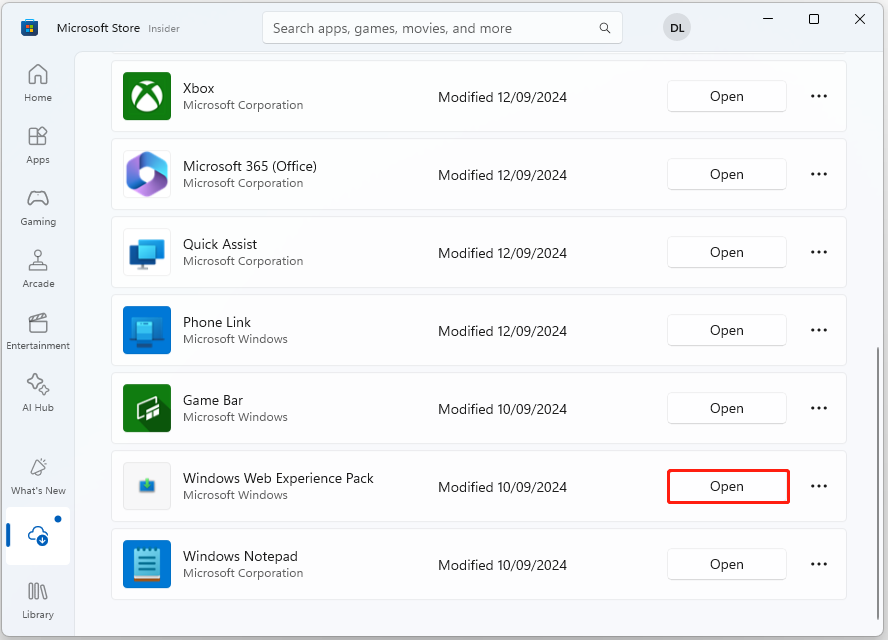

Suggested read: Boost Windows with the Web Experience Pack Download

These facets of weather conditions exert a considerable influence on the outcome of any attempt to alter the color of PVC window frames. Neglecting these environmental considerations increases the risk of paint failure, necessitating costly repairs and potentially damaging the underlying PVC material. Successful projects, therefore, require careful planning and execution that take into account the prevailing atmospheric conditions, ensuring optimal adhesion, curing, and long-term durability.

5. Long-Term Durability

The long-term viability of altering the color of PVC window frames is intrinsically linked to the durability of the applied coating. Initial aesthetic appeal is secondary to the coating’s capacity to withstand environmental stressors, maintain its integrity, and resist degradation over extended periods. Factors influencing this durability are multifaceted and demand meticulous consideration.

-

UV Resistance

Ultraviolet radiation is a primary catalyst for paint degradation. Prolonged exposure to sunlight causes fading, chalking, and embrittlement of the coating, particularly in formulations lacking adequate UV inhibitors. The implications for PVC window frames are significant; without sufficient UV resistance, the altered color will degrade prematurely, necessitating frequent repainting. For example, a dark-colored paint without UV protection may fade significantly within a year, while a similar paint with UV inhibitors could maintain its color for five years or more.

-

Resistance to Thermal Expansion and Contraction

PVC exhibits a relatively high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature fluctuations. A rigid coating incapable of accommodating these movements will likely crack or peel. The use of flexible coatings formulated specifically for vinyl is crucial to mitigate this risk. These coatings are engineered to expand and contract with the PVC substrate, maintaining adhesion and preventing premature failure. Failure to select a flexible coating can result in visible cracks along the window frame within a single season.

-

Adhesion Integrity

The strength of the bond between the coating and the PVC substrate is paramount to long-term durability. Poor adhesion leads to peeling and blistering, compromising both the aesthetic appeal and protective function of the paint. Surface preparation, including thorough cleaning and the application of a bonding primer, is critical to establishing a strong and durable bond. Contaminants on the PVC surface, such as dirt or grease, can significantly weaken adhesion, resulting in premature coating failure. A well-prepared surface, combined with a suitable primer, creates a stable foundation for the topcoat, ensuring long-term adhesion integrity.

-

Resistance to Moisture and Chemical Exposure

Exterior coatings are continuously exposed to moisture, including rain, snow, and condensation. The coating’s ability to resist water absorption and prevent the growth of mold and mildew is essential for long-term performance. Furthermore, exposure to common household chemicals, such as cleaning solutions, can degrade certain paint formulations. The selection of a coating with inherent resistance to moisture and chemical exposure is crucial for maintaining its integrity and preventing staining or discoloration. A high-quality exterior paint formulated for vinyl will typically incorporate mildewcides and offer superior resistance to water absorption compared to standard interior paints.

These facets underscore the importance of selecting appropriate materials and techniques when altering the color of PVC window frames. Long-term durability is not merely a matter of aesthetic longevity; it directly impacts the window’s protective function and overall value. Careful consideration of UV resistance, thermal expansion compatibility, adhesion integrity, and resistance to environmental exposure is essential to ensure a lasting and satisfactory result. The decision to paint PVC windows should be informed by a comprehensive understanding of these factors to maximize the investment and minimize the risk of premature failure.

Frequently Asked Questions

This section addresses common inquiries regarding the feasibility and best practices associated with applying a coating to polyvinyl chloride (PVC) window frames. The following questions and answers provide concise information based on industry standards and best practices.

Question 1: What types of paint are suitable for use on vinyl windows?

Acrylic latex paints specifically formulated for use on vinyl or plastic siding are generally recommended. These paints are engineered to exhibit flexibility and adhere effectively to the non-porous surface of PVC.

Question 2: Is surface preparation necessary before painting vinyl windows?

Meticulous surface preparation is essential. The vinyl surface must be thoroughly cleaned to remove dirt, grease, and any existing oxidation. A bonding primer designed for plastics may also be required to ensure adequate paint adhesion.

Question 3: Can dark colors be used when painting vinyl windows?

Dark colors are generally discouraged due to their tendency to absorb excessive heat. This heat absorption can lead to warping or deformation of the vinyl frame. Consult with a paint specialist to explore heat-reflective paint options if a dark color is desired.

Question 4: What environmental conditions are conducive to painting vinyl windows?

Ideal conditions involve moderate temperatures (typically between 50F and 85F) and low humidity. Painting during extreme temperatures or periods of high humidity can compromise paint adhesion and curing.

Question 5: How many coats of paint are typically required for vinyl windows?

Two thin, even coats are generally recommended to achieve optimal coverage and durability. Avoid applying a single thick coat, as this can lead to sagging, runs, and compromised adhesion.

Question 6: What is the expected lifespan of a paint job on vinyl windows?

The lifespan of a paint job on vinyl windows can vary depending on factors such as paint quality, surface preparation, and environmental exposure. A properly executed paint job with high-quality materials can last for several years.

In summary, successful painting of PVC window frames requires careful planning, meticulous execution, and the selection of appropriate materials. Adherence to best practices and industry standards increases the likelihood of a durable and aesthetically pleasing result.

The next section will explore the potential drawbacks and alternative solutions to consider before undertaking this project.

Tips for Successfully Painting Vinyl Windows

Altering the color of PVC window frames requires careful consideration to ensure a durable and aesthetically pleasing outcome. Adherence to established best practices is critical for success.

Tip 1: Select Paints Specifically Formulated for Vinyl. Utilizing standard exterior paints can result in adhesion failures. Formulations designed for vinyl incorporate plasticizers that accommodate thermal expansion and contraction, preventing cracking and peeling.

Tip 2: Prioritize Meticulous Surface Preparation. The presence of dirt, grease, or oxidation compromises paint adhesion. Thorough cleaning with appropriate degreasers and, potentially, light abrasion are essential to create a suitable bonding surface.

Tip 3: Apply Thin, Even Coats. Multiple thin coats provide better adhesion and a more uniform appearance compared to a single, thick coat. Thick coats are prone to sagging and require extended drying times, increasing the risk of imperfections.

Tip 4: Control Environmental Conditions. Avoid painting during periods of extreme temperatures or high humidity. Elevated humidity levels impede drying, while high temperatures can accelerate solvent evaporation, leading to poor adhesion.

Suggested read: RV Windows: Replacement, Repair & More!

Tip 5: Consider the Impact of Color Choice. Dark colors absorb more heat than lighter colors, potentially causing the PVC to warp or distort. When using darker shades, explore heat-reflective paint options to mitigate this risk.

Tip 6: Utilize a Bonding Primer. The application of a bonding primer specifically designed for plastics enhances paint adhesion and creates a uniform surface for the topcoat. This step is particularly beneficial for older or weathered PVC frames.

Tip 7: Adhere to Recommended Drying Times. Allowing adequate drying time between coats is crucial for proper paint curing. Premature application of subsequent coats can trap solvents and lead to blistering or solvent popping.

Consistently implementing these strategies optimizes the likelihood of achieving a durable and visually appealing finish on PVC window frames. By addressing key factors such as paint selection, surface preparation, and environmental conditions, one can minimize the risk of premature coating failure and maximize the longevity of the painted surface.

The concluding section will provide a synthesis of the information presented and offer a final perspective on the viability of painting PVC window frames.

Can You Paint Vinyl Windows

The preceding analysis explored the multifaceted considerations involved in altering the color of PVC window frames. Factors examined included surface preparation, appropriate paint selection, proper application techniques, the influence of environmental conditions, and the critical aspect of long-term durability. Each of these elements plays a vital role in determining the success or failure of such a project. While specialized coatings formulated for vinyl and plastics offer a viable option, meticulous adherence to best practices remains paramount. Deviations from established protocols significantly increase the risk of premature coating failure, potentially compromising the aesthetic appeal and structural integrity of the window frames.

Therefore, individuals contemplating this endeavor should carefully weigh the potential benefits against the inherent challenges and risks. While customization is achievable, success hinges on a commitment to thorough preparation, informed material selection, and diligent execution. A comprehensive understanding of the factors discussed herein is essential for making an informed decision and achieving a lasting, satisfactory result. If uncertainty persists, consultation with a qualified painting professional is strongly advised to ensure a successful and durable outcome.

![Download Toki Pona Language Pack for Windows - [Updated] 19 download toki pona language pack for windows updated](https://superagc.com/wp-content/uploads/2025/10/download-toki-pona-language-pack-for-windows-updated.webp)