The application of film to vehicle or building windows, offered at a significantly reduced cost compared to the market average, constitutes an economy-focused service. This entails a lower financial investment for consumers seeking to alter the light transmission and potentially enhance the aesthetic appeal of their existing glass surfaces. Such installations are often characterized by the use of less expensive materials or streamlined application processes.

Accessible solutions for modifying window properties can broaden the market to include budget-conscious individuals. Historically, such services have provided an entry point for consumers to experience some of the benefits associated with window modifications, like reduced glare and increased privacy, without substantial financial commitment. The perceived value proposition often hinges on balancing cost savings with the longevity and performance of the materials used.

The following sections will delve into considerations regarding the selection process, potential trade-offs in quality, and the long-term value associated with economy-driven window treatments. We will explore factors influencing durability, visual clarity, and protective capabilities against UV radiation and heat gain.

1. Material Grade

The selection of material grade exerts a significant influence on the long-term performance of economically priced window films. Lower-cost options frequently utilize thinner polyester films and less sophisticated adhesive compounds. This directly impacts resistance to scratching, fading, and delamination. For instance, a film employing a dye-based colorant will typically exhibit faster fading under prolonged sun exposure compared to films incorporating ceramic or metallic particle technologies. Consequently, the initial cost savings may be offset by the need for premature replacement, resulting in a higher total cost of ownership.

Furthermore, the grade of the adhesive is critical for proper bonding to the glass surface. Substandard adhesives can lead to bubbling, peeling, or distortion of the film, compromising both aesthetics and functionality. Examples of this are evident in installations where film detachment occurs within a year due to adhesive failure from heat and humidity cycles. The selection of films with robust, pressure-sensitive adhesives is crucial for ensuring a durable bond and preventing these issues, despite the potentially higher upfront material cost.

In summary, while the appeal of reduced initial expenses is understandable, prioritizing material grade when opting for budget-conscious window films is essential. Sacrificing material quality for minimal savings often results in diminished performance and a shortened product lifespan. Balancing cost considerations with performance expectations ensures a more sustainable and effective outcome, avoiding the pitfall of false economy.

Suggested read: Professional Window Tinting Service - Quality Windows

2. Installation Quality

The proficiency and care exercised during the installation process significantly impact the overall success and longevity of window films, particularly when opting for economically priced options. While the materials themselves contribute to the final result, subpar installation can negate the potential benefits of even high-quality films, rendering the initial cost savings irrelevant.

-

Surface Preparation

Thorough cleaning and preparation of the glass surface are critical for proper adhesion. Inadequate removal of contaminants such as dirt, grease, or previous adhesive residue can result in bubbling, peeling, or distortion of the film. For instance, if an installer neglects to properly clean a window before applying a budget film, air pockets may form beneath the film, leading to visual imperfections and reduced performance.

-

Cutting and Trimming Accuracy

Precise cutting of the film to match the window dimensions is essential for a seamless appearance and to prevent edge lifting. Inaccuracies in cutting or trimming can leave unsightly gaps or cause the film to overlap the window frame, creating potential entry points for moisture and debris. An example would be uneven edges on a back window, which not only looks unprofessional, but also might impact visibility.

-

Application Technique

Proper application techniques, including the use of appropriate tools and sufficient slip solution, are vital for achieving a smooth, uniform finish. Incorrect application can lead to creases, wrinkles, or trapped air bubbles that compromise the film’s aesthetic appeal and functionality. Consider an installer rushing the application, resulting in visible creases that affect clarity and heat rejection.

-

Sealing and Edge Treatment

Proper sealing of the film edges is crucial for preventing moisture intrusion and ensuring long-term adhesion. Neglecting to properly seal the edges can result in premature peeling or delamination, particularly in areas exposed to high humidity or frequent washing. For example, failure to seal the top edges can lead to moisture creeping in during rain, causing bubbling or detachment of the film over time.

In conclusion, the quality of installation plays a decisive role in the ultimate success of any window film application. Even the most affordable films can deliver satisfactory results when installed with meticulous attention to detail and adherence to best practices. Conversely, a poorly executed installation can render even premium-grade films ineffective and aesthetically unappealing, underscoring the importance of selecting a skilled and experienced installer, regardless of the chosen film’s price point.

3. UV Protection Level

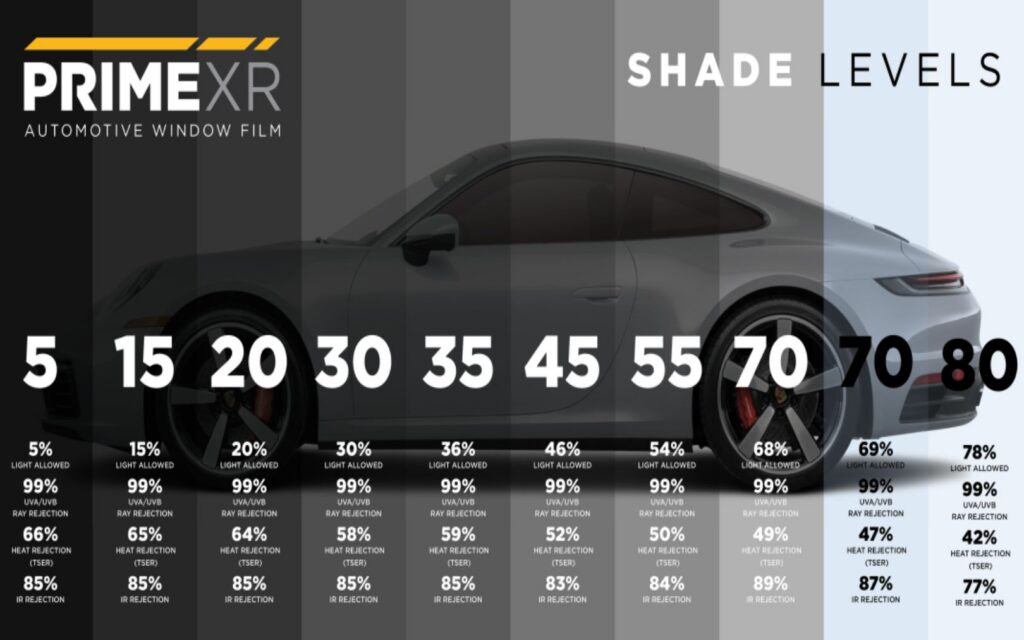

The ultraviolet (UV) protection level afforded by window films, including those marketed as economical options, is a critical performance characteristic directly impacting human health and material preservation. Films lacking adequate UV inhibitors permit the transmission of UVA and UVB radiation, contributing to skin damage, premature aging, and an increased risk of skin cancer with prolonged exposure. Furthermore, unchecked UV radiation accelerates the fading and degradation of interior textiles, dashboards, and upholstery in vehicles, or furnishings within buildings. Economically priced films often utilize less concentrated or less effective UV-absorbing compounds, resulting in reduced protection compared to premium alternatives. For instance, a basic dyed film might block only a fraction of the UV radiation that a multi-layer ceramic film effectively rejects.

The efficacy of UV protection is measurable via spectrophotometry, quantifying the percentage of UV radiation blocked by the film. Reputable manufacturers provide these measurements as part of their product specifications. When considering a budget-friendly option, careful scrutiny of these data points is paramount. It is important to note that even clear films can offer substantial UV protection through the incorporation of UV absorbers, although the level can vary significantly. Practical applications of UV protection extend beyond vehicle and building interiors. Display cases in museums and retail environments benefit from UV-blocking films to preserve sensitive artifacts and merchandise from light-induced damage. Similarly, residential windows fitted with appropriate films can reduce the need for heavy curtains and blinds while maintaining a comfortable and protected interior environment.

In summary, the UV protection level represents a fundamental element in the evaluation of window film, regardless of price point. While economy-focused films may offer a lower initial investment, compromising on UV protection presents long-term risks to human health and material integrity. Informed consumers should prioritize films that demonstrably mitigate UV radiation exposure, even if it necessitates a slightly higher upfront cost. Balancing budgetary considerations with health and preservation concerns ensures a more sustainable and responsible choice in window film selection.

4. Durability Expectations

Durability expectations represent a crucial consideration when evaluating the value proposition of economy-priced window films. The anticipated lifespan and resistance to degradation directly influence the long-term cost-effectiveness and overall satisfaction associated with such installations. Lower initial costs often correlate with reduced durability, requiring careful assessment of trade-offs.

-

Film Thickness and Composition

Thinner films, commonly employed in budget options, exhibit reduced resistance to scratching, abrasion, and impact. The polyester base material may be of a lower grade, leading to diminished tensile strength and increased susceptibility to tearing. For instance, a film with a thickness of 1 mil (thousandth of an inch) is inherently less durable than a 2 mil film, particularly in environments with high traffic or potential for physical contact. The inclusion of protective coatings, such as scratch-resistant layers, further impacts longevity. Films lacking these coatings are more prone to surface damage, compromising appearance and performance.

-

Adhesive Longevity

The adhesive bond between the film and the glass surface is a critical determinant of durability. Economical films may utilize adhesives with lower temperature resistance or reduced resistance to moisture. This can lead to delamination, bubbling, or peeling, particularly in climates with extreme temperature fluctuations or high humidity. An example is the formation of air pockets in the film after a year due to adhesive failure, necessitating premature replacement.

-

Color Stability and Fade Resistance

The color stability of the film is directly related to its composition and resistance to UV radiation. Lower-cost dyed films are susceptible to fading over time, resulting in a change in appearance and reduced glare control. This degradation is exacerbated by prolonged exposure to sunlight. Ceramic or metallic films, while typically more expensive, offer superior fade resistance, maintaining their color and performance characteristics for a longer period. A dyed film on a south-facing window may show significant fading within two years, while a ceramic film retains its color for five years or more.

-

Environmental Factors

Environmental factors, such as exposure to harsh chemicals, frequent cleaning, or extreme weather conditions, significantly impact the durability of window films. Films with a protective topcoat resist damage from cleaning solutions. Films with less robust composition degrade more quickly in polluted environments. These considerations become vital when evaluating options tailored for specific environmental demands.

In summation, aligning durability expectations with the inherent limitations of economy-priced window films is essential for informed decision-making. While the allure of lower initial costs is compelling, a comprehensive assessment of material composition, adhesive properties, color stability, and environmental resilience is paramount. Careful consideration of these factors ensures that the selected film meets the intended performance requirements and delivers a satisfactory return on investment over its expected lifespan.

5. Warranty Provisions

Warranty provisions represent a critical aspect when evaluating budget-conscious window film options. These provisions define the manufacturer’s or installer’s responsibility for addressing defects or premature failure of the product, directly influencing the consumer’s financial risk and long-term satisfaction.

Suggested read: Affordable Window Tinting Price: Get a Quote Now!

-

Scope of Coverage

The scope of coverage delineates the specific issues or defects that are included under the warranty’s protection. Economically priced window film often comes with limited coverage, excluding issues such as fading, bubbling, peeling, or scratches that may arise from normal wear and tear or improper cleaning. For instance, a warranty might cover adhesive failure leading to delamination but exclude damage caused by accidental impact or abrasive cleaning methods. Understanding these limitations is crucial for assessing the true value of the warranty.

-

Duration of Coverage

The duration of coverage specifies the period during which the warranty remains valid. Budget-friendly options typically feature shorter warranty periods compared to premium alternatives. A standard warranty for an economy film might extend for one to three years, while higher-end films may offer coverage for five years or more. The shorter duration increases the likelihood of incurring out-of-pocket expenses for repairs or replacements should issues arise after the warranty expires. This necessitates careful consideration of the expected lifespan and potential degradation rate of the film.

-

Claim Procedures and Requirements

Claim procedures and requirements outline the steps necessary to file a warranty claim and the supporting documentation required. Some warranties mandate professional inspection and documentation of the defect by an authorized installer, potentially incurring additional costs for the consumer. Furthermore, certain warranties may require the original proof of purchase and installation date, which can be difficult to produce if lost or misplaced. Understanding these procedures is essential for ensuring a smooth and efficient claims process in the event of a warranty-covered issue.

-

Transferability Provisions

Transferability provisions dictate whether the warranty can be transferred to a subsequent owner of the vehicle or building. Many warranties on budget-conscious window film are non-transferable, limiting the value proposition for those planning to sell or lease their property. A transferable warranty can enhance the resale value and provide added peace of mind for potential buyers, making it a significant differentiator between different warranty offerings.

In conclusion, a thorough evaluation of warranty provisions is paramount when considering economy window film. The scope, duration, claim procedures, and transferability all contribute to the overall value and risk associated with the product. While a low initial price may seem appealing, understanding the limitations of the warranty is essential for making an informed decision and avoiding potential future expenses. Scrutinizing these factors ensures a balanced assessment of cost versus protection, leading to greater long-term satisfaction.

Frequently Asked Questions About Inexpensive Window Tinting

The following section addresses common inquiries regarding the attributes, limitations, and considerations associated with budget-friendly window film applications. These questions aim to provide clarity and informed perspectives to prospective consumers.

Question 1: What is the typical lifespan expected from economy window tinting?

The durability of economy window tinting is generally lower than premium alternatives. A lifespan of 1-3 years is common, influenced by climate and maintenance. Premium films often exceed 5 years.

Question 2: Does low-cost window tinting provide adequate UV protection?

The level of UV protection can vary significantly. It is crucial to verify the UV rejection specifications from the manufacturer. Some cheaper options offer minimal UV blockage, while others offer sufficient coverage.

Question 3: What are the potential drawbacks of choosing cheap window tinting?

Potential drawbacks include premature fading, bubbling, peeling, scratching, and reduced heat rejection compared to higher-quality films. Installation flaws are more noticeable due to less forgiving materials.

Question 4: How does the installation quality affect the performance of budget-friendly window tinting?

Installation quality is paramount. Even high-grade films perform poorly with substandard installation. Proper surface preparation and precise application are essential for longevity.

Question 5: Are there specific maintenance requirements for inexpensive window tinting?

Gentle cleaning practices are recommended. Avoid abrasive cleaners or harsh scrubbing. Use a soft cloth and mild, non-ammonia based cleaning solutions.

Question 6: Does the cost of cheap window tinting include a warranty, and what does it cover?

Warranty coverage varies greatly. Some installations offer limited or no warranty. Scrutinize the warranty terms, particularly regarding defects, fading, and installation errors.

In summary, inexpensive window tinting can offer an initial cost saving but demands careful assessment of potential drawbacks and limitations. Prioritizing installation quality and verifying key performance characteristics is essential for maximizing the value and satisfaction derived from such applications.

The following section transitions to a discussion of alternatives to budget options and factors to consider when investing in higher-quality window films.

Navigating Economical Window Film Applications

Achieving satisfactory results from lower-cost window film installations necessitates meticulous planning and execution. The following tips offer guidance on optimizing the value and longevity of such applications.

Tip 1: Prioritize Installer Expertise.

The installer’s skill directly impacts the outcome. Verify credentials, request references, and inspect prior installations before entrusting the project to any installer. Proper surface preparation and application techniques are crucial, regardless of film price.

Tip 2: Scrutinize Product Specifications.

Do not rely solely on price. Obtain detailed specifications regarding UV rejection, visible light transmission, and total solar energy rejection. Compare these values across different films to make an informed decision.

Tip 3: Manage Expectations Regarding Longevity.

Budget-friendly films typically have a shorter lifespan. Be prepared for potential replacement within 1-3 years, depending on climate exposure and maintenance practices. Factor this into the overall cost analysis.

Tip 4: Perform Regular Maintenance.

Gentle cleaning is essential. Use a soft cloth and mild, non-ammonia based cleaner. Avoid abrasive materials or harsh chemicals that can damage the film surface and accelerate degradation.

Tip 5: Inquire About Warranty Coverage.

Suggested read: Auto Window Tinting Cost: Get A Quick Quote & Save!

Understand the warranty terms explicitly. Many economical films offer limited or no warranty. Document all installation details and retain proof of purchase to facilitate any future claims.

Tip 6: Consider Gradual Upgrades.

If budget constraints are significant, consider applying higher-quality film to the most critical windows (e.g., those facing direct sunlight) and economizing on less exposed areas. This phased approach optimizes value while addressing key performance requirements.

Implementing these measures can significantly enhance the performance and extend the lifespan of economy window film applications. Informed decision-making and diligent maintenance are essential for maximizing satisfaction.

The following concluding remarks summarize the key considerations discussed throughout this article, offering final guidance on navigating the landscape of window film solutions.

Conclusion

The preceding analysis has explored the multifaceted considerations surrounding cheap window tinting. While the initial cost savings associated with such services may appear attractive, a comprehensive evaluation of material quality, installation expertise, UV protection levels, durability expectations, and warranty provisions is essential. The potential trade-offs between upfront expenses and long-term performance must be carefully weighed to ensure a satisfactory outcome.

Ultimately, the decision to pursue cheap window tinting should be guided by a thorough understanding of the inherent limitations and potential risks involved. Prudent consumers are encouraged to prioritize informed decision-making, seeking transparent product specifications and reliable installation services. Balancing budgetary constraints with performance requirements remains paramount for achieving a responsible and sustainable solution.

![Download Toki Pona Language Pack for Windows - [Updated] 19 download toki pona language pack for windows updated](https://superagc.com/wp-content/uploads/2025/10/download-toki-pona-language-pack-for-windows-updated.webp)